In modern manufacturing, quality control is a top priority. No business wants to release defective products that could harm its reputation, lead to costly recalls, or cause customer dissatisfaction. That’s why End-of-Line (EOL) testing has become an essential part of production processes across industries.

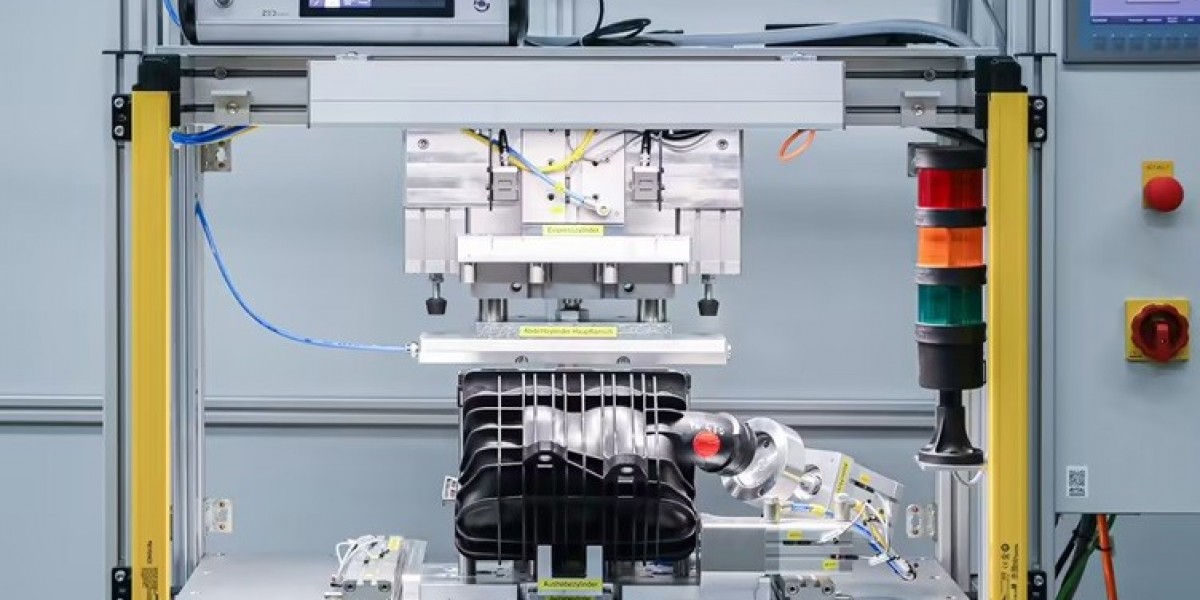

An EOL tester helps manufacturers detect defects, verify product functionality, and ensure that every unit meets strict quality standards before reaching the customer. Unlike generic testing solutions, a Bespoke EOL tester is customized to match specific production requirements, offering greater accuracy and efficiency. Bespoke EOL tester solutions can be integrated seamlessly into production lines, helping businesses maintain high standards while improving overall workflow.

What Is an EOL Tester?

An EOL tester is an automated system used to evaluate a product’s performance, durability, and safety at the final stage of production. It runs various tests to ensure that the product functions as expected and complies with industry standards before being shipped to customers.

Depending on the industry, EOL testers can assess different factors, including:

- Electrical performance

- Mechanical integrity

- Software functionality

- Environmental resistance

- Safety compliance

By identifying defects early, an EOL tester helps prevent costly failures and enhances customer satisfaction.

How EOL Testing Improves Your Production Line

1. Detects Defects Before Shipment

No manufacturer wants to deal with product returns or negative customer feedback. An EOL tester ensures that every unit leaving the production line is thoroughly checked for defects, reducing the risk of faulty products reaching the market.

2. Enhances Product Quality

By verifying that each product meets high-quality standards, an EOL tester helps maintain consistency across all production batches. This is particularly important in industries such as automotive, aerospace, and medical devices, where precision is critical.

3. Reduces Manual Inspection Effort

Manual testing can be time-consuming and prone to human error. An automated EOL tester speeds up the process and delivers more reliable results, allowing manufacturers to focus their workforce on other essential tasks.

4. Increases Production Efficiency

Integrating an EOL tester into your manufacturing process minimizes bottlenecks, optimizes workflow, and ensures faster turnaround times. This means higher productivity and greater output without compromising quality.

5. Ensures Compliance with Industry Standards

Many industries have strict regulations that manufacturers must follow. EOL testers help ensure that products comply with safety and performance standards, preventing legal issues and costly penalties.

Industries That Benefit from EOL Testers

1. Automotive Industry

Car manufacturers use EOL testers to evaluate components such as engines, braking systems, and electronic control units. These tests ensure vehicles meet safety regulations and performance standards before leaving the factory.

2. Electronics Manufacturing

From smartphones to circuit boards, electronic devices require rigorous testing to confirm functionality. EOL testers verify electrical performance, software integration, and component reliability.

3. Medical Device Production

Precision and safety are critical in medical device manufacturing. EOL testers ensure that equipment such as ventilators, diagnostic machines, and surgical tools function correctly before they reach healthcare facilities.

4. Aerospace and Defense

Aerospace components undergo extreme conditions, making high-quality testing essential. EOL testers help verify the durability and safety of flight control systems, navigation instruments, and communication devices.

5. Industrial Machinery

Heavy equipment manufacturers rely on EOL testers to check machinery performance, ensuring that industrial tools and automated systems work efficiently under demanding conditions.

Key Features of a Bespoke EOL Tester

1. Customization for Specific Needs

A Bespoke EOL tester is designed to match your production line’s unique requirements. Unlike generic testers, customized solutions ensure that all critical product aspects are evaluated thoroughly.

2. Integration with Existing Systems

Modern EOL testers can be seamlessly integrated into automated production lines, ensuring smooth operation without disrupting workflow.

3. Real-Time Data and Analytics

Advanced EOL testers provide detailed reports and real-time monitoring, helping manufacturers identify patterns and improve production processes.

4. Scalability for Future Growth

A tailored EOL tester can adapt to future production changes, making it a long-term investment that grows with your business.

5. Automated Fault Detection

With AI-driven diagnostics and automated fault detection, an EOL tester can pinpoint defects more accurately than manual inspection methods.

How to Implement an EOL Tester in Your Production Line

1. Analyze Your Testing Needs

Start by assessing the critical aspects of your product that need evaluation. Identify key performance indicators to determine the type of EOL testing required.

2. Choose the Right Testing Solution

Decide whether you need a standard testing system or a Bespoke EOL tester designed specifically for your industry. Custom solutions provide better accuracy and efficiency.

3. Work with Experts for Seamless Integration

Collaborate with automation specialists to design and implement an EOL tester that fits seamlessly into your production process. This ensures smooth adoption and minimal downtime.

4. Train Your Team for Optimal Use

Providing proper training for your workforce ensures they can efficiently operate and maintain the EOL tester, maximizing its benefits.

5. Monitor Performance and Make Improvements

Use real-time analytics to track the performance of your EOL tester. Regularly update and optimize your testing processes to improve efficiency.

The Future of EOL Testing in Manufacturing

The role of EOL testing is expanding as industries embrace automation and digital transformation. Future advancements in EOL testing include:

- AI-driven defect detection for higher accuracy

- IoT connectivity for remote monitoring and predictive maintenance

- Cloud-based data analysis for better production insights

- Machine learning integration to continuously improve testing efficiency

With these advancements, manufacturers will benefit from even more reliable and intelligent quality control systems.

Final Thoughts

Investing in an EOL tester is a game-changer for manufacturers looking to improve product quality, enhance efficiency, and ensure compliance with industry regulations. A Bespoke EOL tester takes things a step further by offering customized testing solutions tailored to specific production needs.

By implementing an advanced EOL testing system, businesses can reduce defects, streamline operations, and maintain a competitive edge in their industry. If you want to optimize your production process, now is the time to explore a customized EOL testing solution.