Introduction

The Automotive Radiator Manufacturing Plant Project Report provides an extensive overview of establishing a manufacturing plant focused on producing automotive radiators. Radiators are critical components in the automotive industry, playing a vital role in engine cooling systems. As the global automotive industry continues to expand, especially in emerging markets, the demand for efficient and reliable radiators is on the rise. This report offers insights into the production processes, market trends, financial projections, and essential factors for successfully setting up an automotive radiator manufacturing plant.

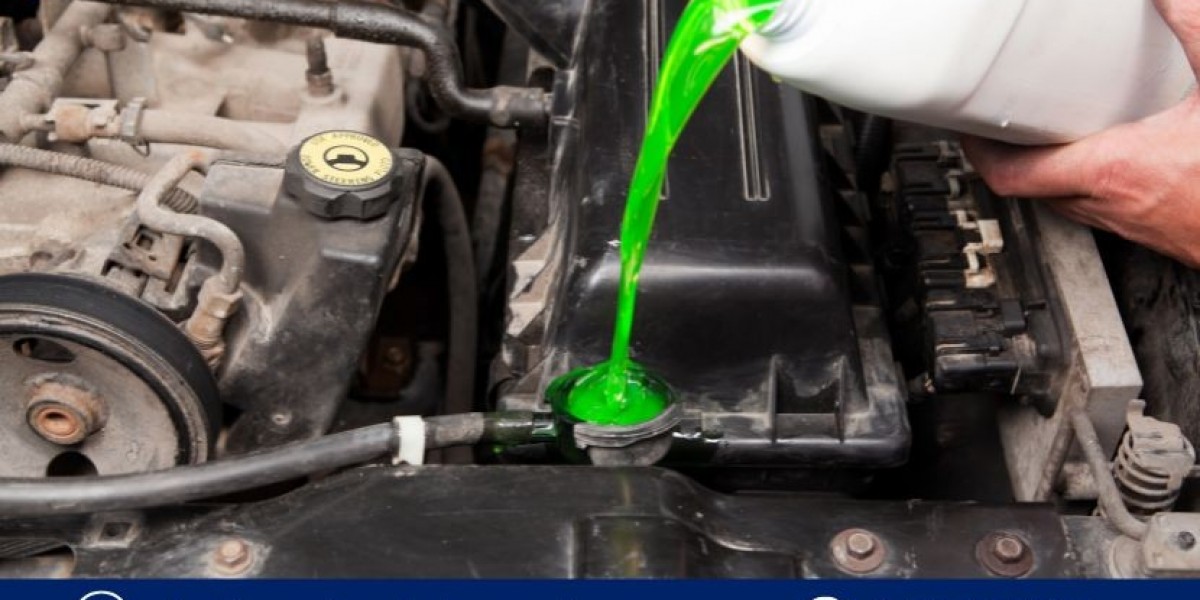

Automotive radiators are designed to cool the engine by dissipating heat from the coolant that circulates through the engine block. As vehicles become more advanced, the need for high-performance radiators that offer improved heat dissipation, energy efficiency, and durability continues to grow. The automotive radiator market is expected to expand as new vehicles are manufactured and existing vehicles require radiator replacements. This report aims to assist manufacturers, investors, and entrepreneurs in understanding the complexities and potential of entering the automotive radiator production market.

Market Overview

Automotive Radiator Market Demand

The global demand for automotive radiators is driven by several factors:

- Growing Automotive Industry: As car production continues to rise worldwide, particularly in emerging markets like China, India, and Latin America, the demand for automotive radiators has been steadily increasing.

- Vehicle Maintenance: Radiators are subject to wear and tear over time, which means there is a consistent replacement market for radiators. The growing vehicle fleet on roads creates a substantial aftermarket demand for replacement radiators.

- Technological Advancements: Innovations in radiator materials and designs have improved performance, leading to a shift toward more efficient radiators that can handle the increasing engine temperatures of modern vehicles.

- Fuel Efficiency and Environmental Concerns: As the automotive industry moves towards more energy-efficient vehicles, including electric and hybrid vehicles, there is an increased emphasis on optimizing engine cooling systems to enhance fuel efficiency.

The market is highly competitive, with several major players in the radiator manufacturing industry. However, the increasing adoption of advanced cooling technologies and the growing automotive market present significant opportunities for new entrants in the field.

Get a Free Sample Report with Table of Contents@

Objectives of the Automotive Radiator Manufacturing Plant

The establishment of an automotive radiator manufacturing plant has the following objectives:

- Production of High-Quality Radiators: To produce radiators that meet international industry standards for heat dissipation, durability, and efficiency.

- Cost Efficiency: To optimize the production process to ensure competitive pricing and achieve cost-effectiveness through economies of scale.

- Market Penetration: To capture a significant share of the growing global automotive radiator market by targeting both OEM (Original Equipment Manufacturer) and aftermarket segments.

- Sustainability: To implement eco-friendly manufacturing practices and use sustainable materials to reduce the plant’s carbon footprint.

- Technological Innovation: To incorporate the latest technologies in radiator design and production processes to meet the increasing demand for more efficient, lightweight, and durable products.

Plant Design and Layout

Facility Design

The design of an automotive radiator manufacturing plant should focus on efficient space utilization, smooth workflow, and ensuring compliance with industry safety standards. Key components of the plant design include:

Raw Material Storage: Radiators are typically made from aluminum, copper, or a combination of both. The facility will require designated storage areas for raw materials, ensuring proper inventory management to avoid production delays.

Manufacturing Area: The core area of the plant where radiator components are fabricated, assembled, and tested. This section will house machinery such as heat exchangers, fin presses, and assembly lines for welding and brazing the radiators.

Testing and Quality Control Area: Radiators need to undergo stringent testing to ensure they meet performance standards. This section will include equipment for testing heat transfer efficiency, pressure resistance, and durability.

Packaging and Shipping: The final product will be packaged for shipment to customers, including OEMs and distributors. Packaging must protect the radiators during transit and ensure the products are delivered in good condition.

Manufacturing Process

The automotive radiator manufacturing process involves several key steps:

Material Sourcing: High-quality aluminum, copper, and brass are the primary materials used in radiator production. These materials must be sourced from reliable suppliers to ensure the radiators' performance and longevity.

Heat Exchanger Fabrication: The core of the radiator is the heat exchanger, which consists of a series of tubes and fins. These are created by cutting and shaping metal sheets, followed by assembling them into the heat exchanger structure.

Fin Pressing: The fins of the radiator, which help increase surface area for heat dissipation, are made using specialized fin-pressing machines. These fins are typically made of aluminum or copper and are attached to the radiator core.

Welding and Brazing: Once the heat exchanger and fins are assembled, the parts are welded or brazed together to form a secure bond that ensures the radiator can withstand high temperatures and pressure.

Testing: After assembly, each radiator undergoes rigorous testing. This may include pressure testing, heat dissipation testing, and testing for leaks to ensure the radiator meets the necessary quality standards.

Finishing and Packaging: After successful testing, radiators are cleaned, coated (if necessary), and packaged for distribution. This ensures that they are protected from environmental factors such as moisture, dirt, and corrosion during shipping.

Technology and Equipment

To produce high-quality automotive radiators, the following equipment is necessary:

- Aluminum and Copper Rolling Machines: These machines roll the raw materials into thin sheets, which are then used to create the radiator’s fins and tubes.

- Heat Exchanger Machines: Machines that cut, form, and assemble the components of the heat exchanger. These machines are critical for achieving precise and efficient radiator designs.

- Brazing and Welding Equipment: Radiator components are welded or brazed to form a durable, leak-proof bond. High-quality brazing furnaces and welding machines are essential for ensuring strong, reliable joints.

- Pressure Testing Machines: To test the radiator’s resistance to high pressures, machines that simulate real-world operating conditions are necessary.

- Fin Pressing Machines: Specialized presses are used to shape and attach fins to the radiator core.

Regulatory Compliance and Quality Control

Regulatory Considerations

The automotive radiator manufacturing process is subject to strict industry standards and regulations to ensure product safety, quality, and environmental sustainability. Key regulatory aspects include:

- ISO Certification: The plant must comply with ISO 9001 standards for quality management systems. This ensures the radiators are consistently manufactured to meet customer requirements and industry standards.

- Automotive Standards: Radiators must comply with specific automotive industry standards such as SAE (Society of Automotive Engineers) and IATF 16949, which focus on the manufacturing processes, quality control, and safety requirements for automotive parts.

- Environmental Regulations: Compliance with environmental laws is critical to minimizing the plant’s ecological footprint. Regulations regarding emissions, waste management, and water usage must be followed to ensure sustainability.

Quality Control

A robust quality control process is essential for ensuring the radiators meet industry standards and customer expectations. Key quality control measures include:

- Material Testing: All raw materials must be tested for quality and compliance with specifications before they are used in production.

- Dimensional Inspection: Each radiator is inspected for dimensional accuracy to ensure proper fit and performance.

- Performance Testing: The radiators undergo pressure tests, heat dissipation tests, and other functional tests to ensure they can operate efficiently under high temperatures.

- Visual Inspection: After assembly, the radiators are visually inspected to identify any defects, such as leaks or imperfections in the fin assembly.

Market Opportunities and Financial Analysis

Market Opportunities

Several key trends present opportunities for growth in the automotive radiator manufacturing market:

- Growth in Electric and Hybrid Vehicles: As electric and hybrid vehicle production increases, there will be a higher demand for specialized radiators designed for these vehicles, which require efficient cooling systems to manage battery temperatures.

- Replacement Market: The existing fleet of vehicles worldwide creates a large market for replacement radiators, ensuring consistent demand for aftermarket products.

- Advanced Cooling Solutions: The growing trend towards high-performance vehicles, including sports cars and luxury models, has led to an increased demand for advanced radiators that offer superior heat dissipation.

Financial Considerations

Setting up an automotive radiator manufacturing plant requires substantial capital investment. Financial considerations include:

- Capital Investment: The initial investment will cover the cost of land, plant construction, machinery, raw materials, and workforce.

- Operating Costs: Ongoing expenses include raw material procurement, labor, energy costs, and maintenance of machinery.

- Revenue Projections: The revenue generated will depend on the production capacity, pricing strategy, and demand in the OEM and aftermarket sectors.

Profitability will be influenced by the ability to optimize the manufacturing process, maintain high-quality standards, and establish a strong customer base.

Sustainability and Environmental Impact

Sustainability is a key consideration in modern manufacturing practices. The automotive radiator manufacturing plant can adopt several eco-friendly practices:

- Energy Efficiency: Using energy-efficient equipment and renewable energy sources can help reduce the plant's carbon footprint.

- Material Recycling: Scrap materials, such as metal waste, can be recycled and reused in production to minimize waste and reduce costs.

- Waste Management: Proper disposal and recycling of hazardous materials and waste from the production process are essential for environmental protection.