Introduction

The global seafood industry is vast and ever-growing, with products like anchovies being in high demand for their unique flavor and numerous culinary applications. The Anchovies Manufacturing Plant Project Report serves as a vital tool for those looking to set up a plant that produces anchovies for local and international markets. Anchovies are highly valued in various industries, from food processing and restaurant chains to the production of sauces, pastes, and even in the production of fish oil. The production of anchovies, often known for their preserved forms (salted, canned, or jarred), can be a lucrative venture due to their consistent demand and versatile uses.

This article delves into the essential steps involved in establishing an anchovy manufacturing plant, including market potential, feasibility studies, plant design, the production process, and financial projections. Whether you’re an investor, entrepreneur, or someone interested in the seafood sector, this guide will provide a comprehensive understanding of how to set up and run a successful anchovy manufacturing plant.

What are Anchovies?

Anchovies are small, saltwater fish commonly found in oceans and seas worldwide. They are an essential source of protein and are prized for their intense, savory flavor, often described as “umami.” Typically, anchovies are caught in large quantities and preserved in various forms, including:

Salted and Canned Anchovies: These are the most common forms of anchovies consumed worldwide. The fish are preserved in salt and then packed in cans or jars for distribution.

Anchovy Paste: Made from ground anchovies mixed with other ingredients, anchovy paste is used as a condiment in cooking, especially in Mediterranean and Italian cuisines.

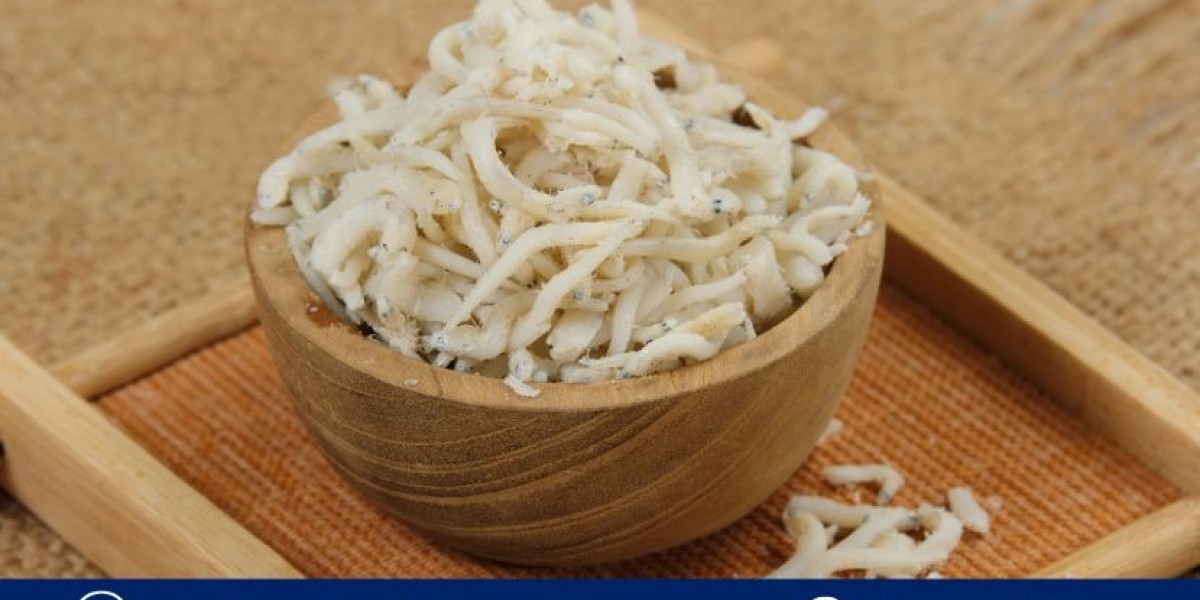

Dried Anchovies: In some cultures, anchovies are dried and used as a flavoring agent in soups, broths, or snacks.

The primary consumers of anchovies include restaurants, food manufacturers, and individuals who use them as a flavor enhancer in dishes like Caesar salad dressing, pasta sauces, and pizzas. The nutritional value of anchovies, including their high levels of omega-3 fatty acids, calcium, and protein, makes them a popular choice in healthy diets.

Get a Free Sample Report with Table of Contents@

Market Analysis and Demand for Anchovies

The market for anchovies is driven by several factors, including:

Culinary Use: Anchovies are widely used in Mediterranean, European, and Asian cuisine. Their application as a flavor enhancer, particularly in sauces like Worcestershire sauce, dressings, and spreads, has led to consistent demand from the food processing industry.

Health and Nutritional Benefits: With growing awareness of the health benefits of omega-3 fatty acids and lean protein, anchovies have gained popularity among health-conscious consumers.

Export Markets: Anchovies are in high demand in global export markets, particularly in Europe, North America, and Asia. Countries like Italy, Spain, and France use anchovies extensively in their traditional dishes, making them significant importers of anchovy products.

Sustainability and Fisheries: Anchovies are relatively abundant in the world’s oceans, ensuring a stable supply of raw materials. Sustainable fishing practices are vital to maintaining the health of anchovy populations, and consumers are increasingly seeking sustainably sourced anchovy products.

Given these factors, establishing an anchovy manufacturing plant presents strong business opportunities, especially if one is targeting both local and export markets.

Feasibility Study and Project Scope

A successful Anchovies Manufacturing Plant Project Report begins with a thorough feasibility study. This includes the evaluation of raw material availability, production processes, market demand, investment costs, and financial viability.

The key aspects to consider are:

Raw Material Supply: Anchovies are typically sourced through fishing fleets or partnerships with local fishers. Securing a reliable and sustainable supply of anchovies is crucial for ensuring consistent production.

Production Process: The plant will need to establish efficient processing systems for cleaning, filleting, salting, packaging, and preserving the anchovies.

Market Demand: Conducting a market analysis will help determine the target customer base (food manufacturers, restaurants, supermarkets) and forecast sales potential.

Investment Costs: A detailed breakdown of the costs involved in setting up the plant, including land, equipment, raw materials, labor, and regulatory compliance, is crucial for planning the financial aspects of the project.

Plant Layout and Design

Designing the plant layout involves creating an efficient workflow that optimizes production and ensures safety, hygiene, and product quality. The key areas to consider in the plant layout are:

Receiving and Storage Area: The anchovies should be received fresh and stored in a refrigerated area to prevent spoilage. The storage facility must be capable of handling large quantities of fish.

Processing Area: This area includes stations for cleaning, gutting, filleting, salting, and possibly smoking the anchovies. The processing area must meet stringent hygiene standards to ensure food safety.

Packaging Section: After processing, anchovies are packaged into cans, jars, or vacuum-sealed pouches. The packaging area must be equipped with automated filling and sealing machines to handle the high throughput efficiently.

Storage and Distribution: Finished products should be stored in a temperature-controlled warehouse before being distributed to retailers, food manufacturers, or exporters.

Waste Management: Fish waste, such as bones, skin, and offcuts, must be disposed of properly to prevent contamination. Some by-products can be processed into fishmeal or used in other industries, reducing waste and enhancing sustainability.

Production Process and Technology

The production of anchovies involves several key stages, each of which requires specialized equipment and technology. Here’s an overview of the basic steps:

Catching and Receiving: Anchovies are caught in large quantities using fishing vessels. Upon arrival at the plant, they are sorted and inspected for quality.

Cleaning and Filleting: The anchovies are washed, cleaned, and filleted to remove inedible parts such as heads, tails, and bones. The filleting process can be done manually or with machines, depending on the scale of production.

Salting and Preservation: Salt is applied to the anchovies to preserve them. This can be done by layering salt between the anchovies and allowing them to cure in large vats for several days or weeks, depending on the desired product.

Canning or Jarring: Once cured, the anchovies are packed into cans or jars, sometimes along with olive oil or other preservatives. The containers are sealed to ensure the product remains fresh and safe for consumption.

Labeling and Packaging: The final step involves labeling the products and preparing them for shipment. The packaging should be attractive and informative to meet consumer expectations and regulatory requirements.

Regulatory and Environmental Considerations

Given that anchovy production involves food processing, strict adherence to local and international food safety and hygiene standards is essential. The plant must comply with regulations established by agencies like:

Food and Drug Administration (FDA) or equivalent national agencies that oversee food safety standards.

Environmental Protection Agency (EPA) for wastewater disposal, waste management, and emissions.

Additionally, ensuring sustainability in anchovy fishing practices is vital. The plant must source anchovies from fisheries that follow sustainable fishing practices to prevent overfishing and environmental degradation.

Financial Projections and Investment Analysis

The Anchovies Manufacturing Plant Project Report should also include a detailed financial analysis. Key components of the analysis include:

- Initial Investment: The costs associated with setting up the plant, including land acquisition, machinery, raw materials, and working capital.

- Operating Costs: Ongoing costs such as labor, utilities, raw material procurement, packaging, and transportation.

- Revenue Projections: Estimating sales based on market demand and product pricing. The report should outline revenue forecasts for the first few years of operation.

- Break-even Analysis: A critical financial tool to determine when the plant is expected to cover its initial investment and begin generating profits.

- Return on Investment (ROI): The expected profitability and payback period for investors and stakeholders.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au