Computer Numerical Control (CNC) Machines Market Outlook

The global computer numerical control (CNC) machines market size, valued at USD 90.91 billion in 2024, is set to expand significantly in the forecast period from 2025 to 2034. With a projected compound annual growth rate (CAGR) of 7.20%, the market is expected to reach USD 182.20 billion by 2034. CNC machines offer high precision, repeatability, and automation, significantly reducing human error in manufacturing processes. These advantages have made CNC technology indispensable in industries that require customisation, high-quality manufacturing, and the ability to quickly adapt designs and product specifications.

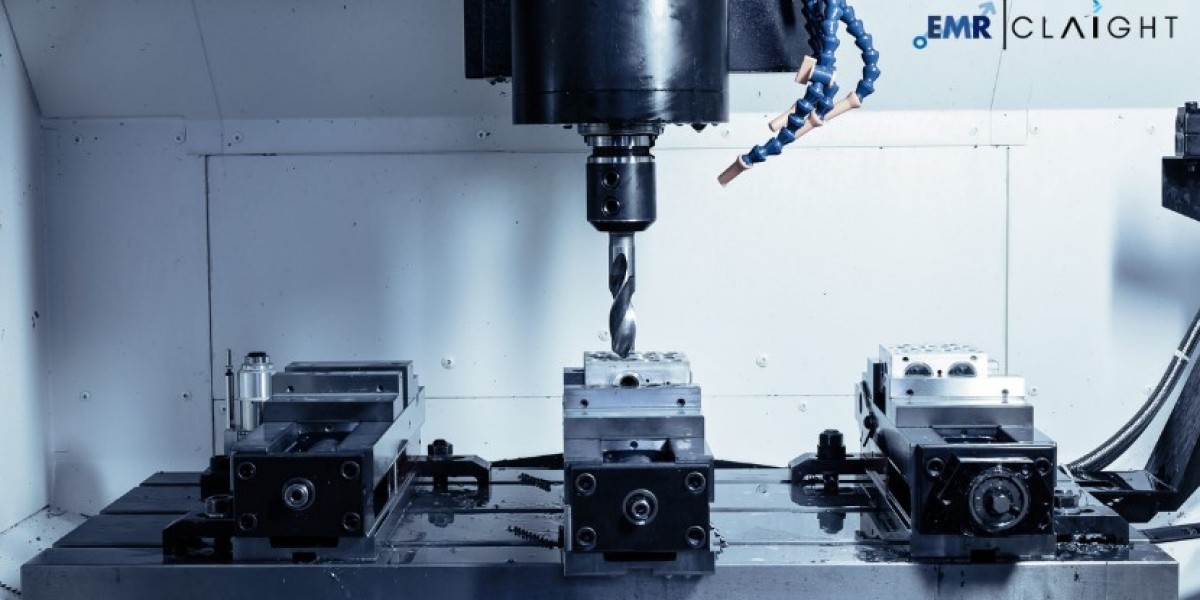

CNC machines are essential for modern manufacturing, allowing for complex and precise machining processes. As industries across the globe increasingly focus on automation and digitalisation to improve efficiency and reduce costs, the demand for CNC machines is expected to rise. Moreover, the ability to easily integrate new designs into production systems, along with the flexibility for customisation, further supports the market's growth.

Computer Numerical Control (CNC) Machines Market Trends

Several key trends are shaping the global CNC machines market and driving its growth. These trends reflect the increasing importance of precision and automation in modern manufacturing:

- Rising Adoption of Automation: One of the key drivers of the CNC machines market is the increasing adoption of automation in various industries. CNC machines are central to the automation trend, as they provide the precision, repeatability, and flexibility needed to meet the demands of modern manufacturing environments. This trend is particularly strong in industries such as automotive and aerospace, where high precision is crucial.

- Demand for Customisation and Flexibility: CNC machines allow manufacturers to quickly adapt their production processes to accommodate custom designs and product specifications. This is particularly important in sectors such as aerospace, automotive, and healthcare, where customisation is a significant competitive advantage. The ability to easily modify production lines and make adjustments without significant downtime is a major factor driving the adoption of CNC technology.

- Technological Advancements in CNC Machines: CNC machines are becoming more advanced with the integration of features like artificial intelligence (AI), the Internet of Things (IoT), and machine learning. These advancements are enhancing the capabilities of CNC machines, allowing for even greater precision, efficiency, and automation. As the manufacturing sector continues to embrace smart technologies, CNC machines are becoming increasingly sophisticated, further driving their demand.

- Growth of Additive Manufacturing: Although CNC machines primarily work through subtractive manufacturing (removing material to create parts), there is growing interest in hybrid CNC machines that combine both subtractive and additive manufacturing capabilities. These machines can create parts using both traditional machining methods and 3D printing technologies, offering greater versatility in production processes.

- Increased Use of CNC in Healthcare: The healthcare industry is increasingly adopting CNC machines for manufacturing medical devices, implants, and surgical instruments. These machines are essential for creating highly precise components that meet stringent quality standards. The growing demand for personalised healthcare solutions and medical innovations is expected to further fuel the adoption of CNC technology in this sector.

Get a Free Sample Report with Table of Contents@https://www.expertmarketresearch.com/reports/computer-numerical-control-machines-market/requestsample

Market Growth

The CNC machines market is projected to grow at a strong rate, with a CAGR of 7.20% from 2025 to 2034. Several factors are contributing to this robust growth:

- Technological Advancements: Continued innovations in CNC machine technology are expected to drive market growth. The integration of AI, IoT, and cloud computing allows for more efficient and smarter CNC operations, reducing errors and improving machine utilisation. Additionally, CNC machines that incorporate hybrid manufacturing methods will offer more versatility in production, opening new opportunities for manufacturers.

- Increasing Demand for High-Precision Parts: Industries such as aerospace, automotive, and electronics require parts that are not only high-quality but also highly precise. CNC machines provide the level of accuracy and consistency that these industries demand, which is helping drive market growth. Additionally, the trend towards miniaturisation of components in electronics and other industries is increasing the need for highly precise manufacturing techniques.

- Growing Need for Efficient Manufacturing Processes: As industries strive to optimise production lines and reduce costs, the demand for CNC machines that can automate complex processes with minimal human intervention is increasing. CNC machines help manufacturers optimise production times, reduce waste, and improve the overall efficiency of manufacturing processes.

- Expansion of Manufacturing Industries in Emerging Markets: The increasing industrialisation in emerging economies, particularly in Asia Pacific, Latin America, and the Middle East, is a significant driver of the CNC machine market. As these regions invest heavily in infrastructure, automotive production, and electronics manufacturing, the demand for CNC machines is expected to rise significantly.

- Rising Demand for CNC Machines in Small and Medium Enterprises (SMEs): While large enterprises have been the primary users of CNC technology, the increasing affordability of CNC machines is making them accessible to small and medium-sized enterprises (SMEs). SMEs in industries such as automotive, electronics, and aerospace are adopting CNC machines to enhance production efficiency and reduce costs.

Market Segmentation

The CNC machines market can be segmented by machine type, end use, and region. Each of these segments plays a crucial role in shaping the overall market dynamics.

Breakup by Machine Type

- Lathe Machines: Lathe machines are among the most commonly used CNC machines, particularly for producing parts that are symmetrical around an axis, such as shafts, cylinders, and discs. They are widely used in the automotive, aerospace, and defence industries for manufacturing complex parts with high precision.

- Milling Machines: Milling machines are versatile CNC machines used for a variety of operations, including drilling, grinding, and cutting. They are particularly used in industries like automotive and aerospace for producing intricate and complex parts. The growing demand for precision parts in these sectors is driving the demand for CNC milling machines.

- Laser Machines: Laser cutting machines use a laser beam to cut materials with high precision. These machines are popular in industries such as electronics, automotive, and healthcare for cutting, engraving, and etching parts. The growing adoption of laser machines in the manufacturing of high-precision components is driving market growth.

- Grinding Machines: CNC grinding machines are used for grinding surfaces and achieving a high degree of surface finish. They are crucial for the production of high-precision components in industries such as aerospace and automotive, where the need for tight tolerances is paramount.

- Welding Machines: CNC welding machines offer automated solutions for welding metal parts with high precision. They are widely used in industries such as automotive and aerospace, where consistent and high-quality welding is essential.

- Winding Machines: CNC winding machines are used for winding wire into coils, particularly in the production of electrical components, transformers, and inductors. The demand for winding machines is expected to rise with the growing production of electrical devices.

- Others: Other CNC machines include specialized machines used for applications such as 3D printing, EDM (Electrical Discharge Machining), and plasma cutting. These niche machines are gaining traction in industries that require specific and specialised manufacturing processes.

Breakup by End Use

- Aerospace and Defence: The aerospace and defence industries require CNC machines for manufacturing high-precision components, including aircraft parts, missiles, and defence equipment. The growing demand for advanced and custom components in these sectors is driving the need for CNC machines.

- Automobiles: CNC machines play a crucial role in the automotive industry, particularly in the production of engine components, transmission systems, and other critical parts. The increasing demand for fuel-efficient and high-performance vehicles is boosting the adoption of CNC machines in automotive manufacturing.

- Electronics: The electronics industry relies heavily on CNC machines for producing components such as circuit boards, connectors, and housings. The increasing miniaturisation of electronics and the demand for high-quality parts is driving the growth of CNC machines in this sector.

- Healthcare: CNC machines are increasingly being used in the healthcare industry for manufacturing medical devices, implants, and surgical instruments. The growing demand for personalised healthcare solutions and medical innovations is expected to further fuel the adoption of CNC machines in this sector.

- Others: CNC machines are also used in various other sectors such as energy, construction, and industrial machinery, where precision and automation are critical for manufacturing complex components.

Breakup by Region

- North America: North America, particularly the United States, is a major market for CNC machines, driven by the presence of key manufacturing industries such as automotive, aerospace, and electronics. The region’s focus on technological innovation and automation is also contributing to market growth.

- Europe: Europe is another key market for CNC machines, with significant demand from countries like Germany, the United Kingdom, and Italy. The automotive and aerospace sectors in Europe are major consumers of CNC machines, and the region’s focus on advanced manufacturing technologies is driving growth.

- Asia Pacific: The Asia Pacific region, particularly China, Japan, India, and ASEAN countries, is experiencing rapid industrial growth and is a significant driver of the CNC machine market. The region’s booming manufacturing sectors, including automotive, electronics, and healthcare, are contributing to increased demand for CNC machines.

- Latin America: Latin America, including countries like Brazil, Argentina, and Mexico, is an emerging market for CNC machines. The increasing industrialisation and growing demand for high-quality manufacturing in sectors like automotive and electronics are driving the adoption of CNC technology.

- Middle East and Africa: The Middle East and Africa are witnessing growing demand for CNC machines, particularly in the oil and gas, aerospace, and automotive sectors. As these industries expand, the need for high-precision machining is expected to increase.

Market Key Players

Several leading companies are driving the growth of the CNC machines market through technological advancements, product innovation, and strategic partnerships:

- HEIDENHAIN Corporation: A global leader in precision measurement and CNC technology, HEIDENHAIN Corporation provides high-performance CNC systems for various industries, including automotive, aerospace, and electronics.

- Soft Servo Systems, Inc.: Soft Servo Systems offers cutting-edge CNC technology solutions focused on providing precise and cost-effective solutions for industrial applications.

- Bosch Rexroth AG: Bosch Rexroth provides a wide range of CNC products, including automation solutions for the manufacturing industry, with a focus on precision, flexibility, and efficiency.

- Mitsubishi Electric Corporation: Mitsubishi Electric is a key player in the CNC machine market, offering a variety of CNC systems for applications in automotive, aerospace, and other industries requiring high-precision components.

- FANUC Corporation: FANUC is a leading provider of CNC machines and robotics solutions, offering products for a wide range of industries, including automotive, electronics, and healthcare.

- Siemens: Siemens offers a broad portfolio of CNC systems, focusing on providing solutions for automation, precision, and efficiency in manufacturing operations.

- Haas Automation, Inc.: Haas Automation is a leading manufacturer of CNC machines, offering a variety of products designed for high precision and automation in industrial applications.

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com